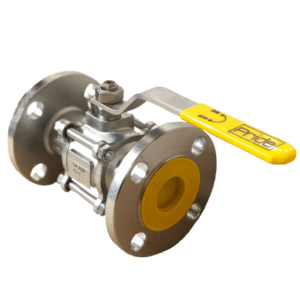

Description

The two-piece ISO 5211 pad ball valve offers a practical way to mount gears or actuators. This valve streamlines the integration process with a specially designed bracket coupler and adapter, ensuring compatibility and ease of use. The flexibility and versatility of industrial applications are increased by the standardization of ISO 5211, which makes it simpler to combine various actuation mechanisms. Its creative design maximizes effectiveness and makes installation easier, making it a dependable option for a range of operational requirements.

Design Features

| MOC | WCB/CF8/CF8M/CF3/CF3M And high nickel Alloys,Etc. |

| Valve Design | Two Piece Construction |

| Size | 15mm to 250mm (1/2″ TO 10″) |

| End Connection | Flanged End (ASME B16.5) |

| Pressure Class | 150# |

| Operation | Manual, Pneumatic Actuator, Electric Actuator & Gear |

| Design & manufacturing Standard | ISO 17292 / BS 5351 / API 6D /ISO 5211 |

| Testing & Inspection | API 598 / BS 6755 |

| Fire Safe | On request |

| Valve Bore | Full Bore |

| Face to Face | ASME B16.10 |

| Temp. Range | -20 TO 180°C |

Technical Specifications

| Name | Details |

|---|---|

| Body | ASTM A216 Gr. WCB / ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| Trail Piece | ASTM A216 Gr. WCB / ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| Ball (Hollow Solid) | ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| Seat Ring | PTFE/GFT/CFT/TFM |

| Body Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| Stem Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| Gland Seal | SS304/SS316/SS304L/SS316L/SS410 |

| Lock Nut | SS202/SS304/SS316/MS |

| Stem | SS304/SS316/SS304L/SS316L/SS410 |

| Handle | SS202/SS304/SS316/CS |

| Sleeve | PVC |

| Bolt | SS202/SS304/SS316/B7/MS |

| Stopping Pin & Nut | SS202/SS304/SS316/MS |

| Gland | SS304/SS316/SS304L/SS316L/SS410 |

Benefits Application

- Full port - higher flow rates & No Pressure Drops

- Blowout-proof Stem Design

- Locking Provision in Open/Close Position on request

- Anti Static Device (On Request)

- Less joint - Chance of low leakage

- Fire Safe Design (On Request)

- More economical than 3-piece Design

- Low cost compared to other full port options

Testing Parameters

| Test Type | Unit-Kg / Cm | Unit-PSIG |

|---|---|---|

| Hydro. Shell | 32 | 430 |

| Hydro Seat | 22M | 315 |

| Air/Pneumatic | 7 | 80 |