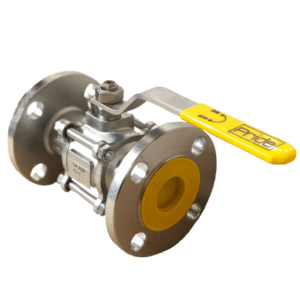

Description

Flush bottom ball valves provide a dependable solution for ensuring tight sealing and preventing leaks while draining fluids or substances from tanks or vessels. Engineered with precision, these valves feature a spherical closure mechanism that efficiently seals against the valve seat, minimizing the risk of leakage. Their design allows for efficient flow control and easy maintenance, making them an essential component in various industrial applications where fluid drainage and leakage prevention are paramount concerns.

Design Features

| MOC | WCB/CF8/CF8M/CF3/CF3M And high nickel Alloys,Etc. |

| Valve Design | Three Piece Construction |

| Size | 25mm to 200mm (1″ TO 8″) |

| End Connection | Flanged End (ASME B16.5) |

| Pressure Class | 150# |

| Operation | Manual |

| Design & manufacturing Standard | BS 5351 |

| Testing & Inspection | API 598 |

| Valve Bore | One Size Reduce Bore |

| Face to Face | Manufacturing Standard. |

| Temp. Range | -20 TO 180°C |

Technical Specifications

| Name | Details |

|---|---|

| Body | ASTM A216 Gr. WCB / ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| Insert | ASTM A216 Gr. WCB / ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| Ball (Solid) | ASTM A351 Gr. CF8/CF8M/CF3/CF3M |

| Seat Ring | PTFE/GFT/CFT/TFM |

| Body Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| Stem Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| Gland Seal | PTFE/GFT/CFT/TFM/GRAFOIL |

| Gland | SS304/SS316/SS304L/SS316L/SS410 |

| Lock Nut | SS202/SS304/SS316/MS |

| Stem | SS304/SS316/SS304L/SS316L/SS410 |

| Handle | SS202/SS304/SS316/CS |

| Sleeve | PVC |

Benefits Application

- Spherical Closure Mechanism

- Blowout-proof Stem Design

- Anti Static Device (On Request)

Testing Parameters

| Test Type | Unit-Kg / Cm | Unit-PSIG |

|---|---|---|

| Hydro. Shell | 32 | 430 |

| Hydro Seat | 22M | 315 |

| Air/Pneumatic | 7 | 80 |